Improving Emergency Response

Intro to Engineering (ENGS 21) is a project-based course at Dartmouth College, where students work for the full 10-week term to design a solution for a problem related to a given prompt. In the Summer Term of 2019, we were challenged to design a solution to improve emergency response.

The Hanover Fire Department came to our course and presented us with their struggle regarding setting up their roadside accident sign. On average, firefighters are injured or killed every 3 days nationwide attending to emergency scenes by passing vehicles. We saw this as a large problem for emergency responders to roadside accidents and wanted to work with the local firefighters to design a better solution. Normally, teams consist of 5-6 members, but our team consisted of 3 passionate members contributing equally in addition to my role as the Team Organizer.

The Problem

Emergency responders are put in danger when attending to roadside accidents and while setting up warning devices in traffic. They are at risk of injury and death by uninformed passing drivers.

User Research

Our team wanted to gain full insights into the problem the firefighters were dealing with, so in addition to sending out a survey to the local fire departments, we visited the Hanover Fire Department numerous times throughout the 10-week course and put ourselves in the user’s shoes. We were able to sit in the truck, understand the tight dimensions in which our solution had to fit in and go through setting up the sign ourselves and watching the firefighters do so themselves.

We were also able to gather valuable insights through our survey responses and a few phone calls with local fire departments. Here are some of the key quotes we took away from our user research:

“ We don’t set up the sign very often. We should set it up every time but the sign is a huge pain in the neck”.

— Matt Swett, Norwich Fire Department

“I avoid setting up the sign because I cut my fingers every time on the spring-loaded pinch points.”

— Corey Bartlett, New London Fire Department

We don’t use the sign, but we carry one on our truck. We try to minimize our time on the road and the sign takes too much time.”

— Jack Hedges, Hartford Fire Department“

“Ideally we would want something that we could huck out the window on the way to the accident.”

— John Emerson, Hanover Firefighter

Initial Brainstorm and Rapid Prototyping

Our team pulled out the whiteboard and conducted a few brainstorming sprints, writing down any ideas that came to mind, or “works like” examples. Some of our rapid prototypes included deployment mechanisms such as inflation, tripod expansion, stop and unfold, and umbrella mechanism. We used materials that we could find around the engineering build such as foam core, tape, springs, and glue.

Initial Solution - Modified Sign

After various types of rapid prototyping and feasibility research, we settled on a spider/umbrella-like design to improve the deployment of the current sign. We made a fully fleshed out prototype in Foamcore, SolidWorks, and then laser cut a wooden prototype based on the SolidWorks dimensions to test with the local fire departments.

User Feedback

We went back to our users to see what they thought. They loved the spider leg deployment method but reiterated that having something they could “huck out the window” on the way to an accident would be better. In addition, our solution had large dimensions that we did not think we could scale down to fit in the cab of the truck. Based on our user’s feedback, we realized that instead of modifying the current solution for a better user experience, we needed to rethink the entire solution to the problem. Our team was 7 weeks into our project with a fleshed-out prototype, but we were determined to go back to the drawing board and design a solution that solved the problem. We remembered that one of the firefighters reported that sign fatigue is a real issue and is becoming more common with construction. We re-accessed our project and set these two new goals that our solution had to address:

Reduce the time spent on the road by firefighters.

Grabs driver’s attention to slow them down (overcome sign fatigue).

Our updated top three specifications were:

Speed of Deployment

Durability

Reliability/Stability

Our team went back to the drawing board and started with sketches and rapid prototyping once again as we pivoted directions towards designing an entirely new solution to the problem we set out to solve.

Some initial ideas included a (1) LED Flare Dropper (2) Temporary Rumble Strips (3) Self Righting Lights (4) Expanding Foam

Prototyping, Product Testing, and User Feedback Revisited

After another round of brainstorming and research, we decided to design a self-righting light that could be thrown out the window onto the road as firefighters make their way to an accident. The self-righting light would be quick to deploy, reducing the time spent on the road by firefighters and it would grab driver’s attention, overcoming sign fatigue. Research has shown that a combination of red and blue lights (what cops and firefighters use) gain the most attention from people.

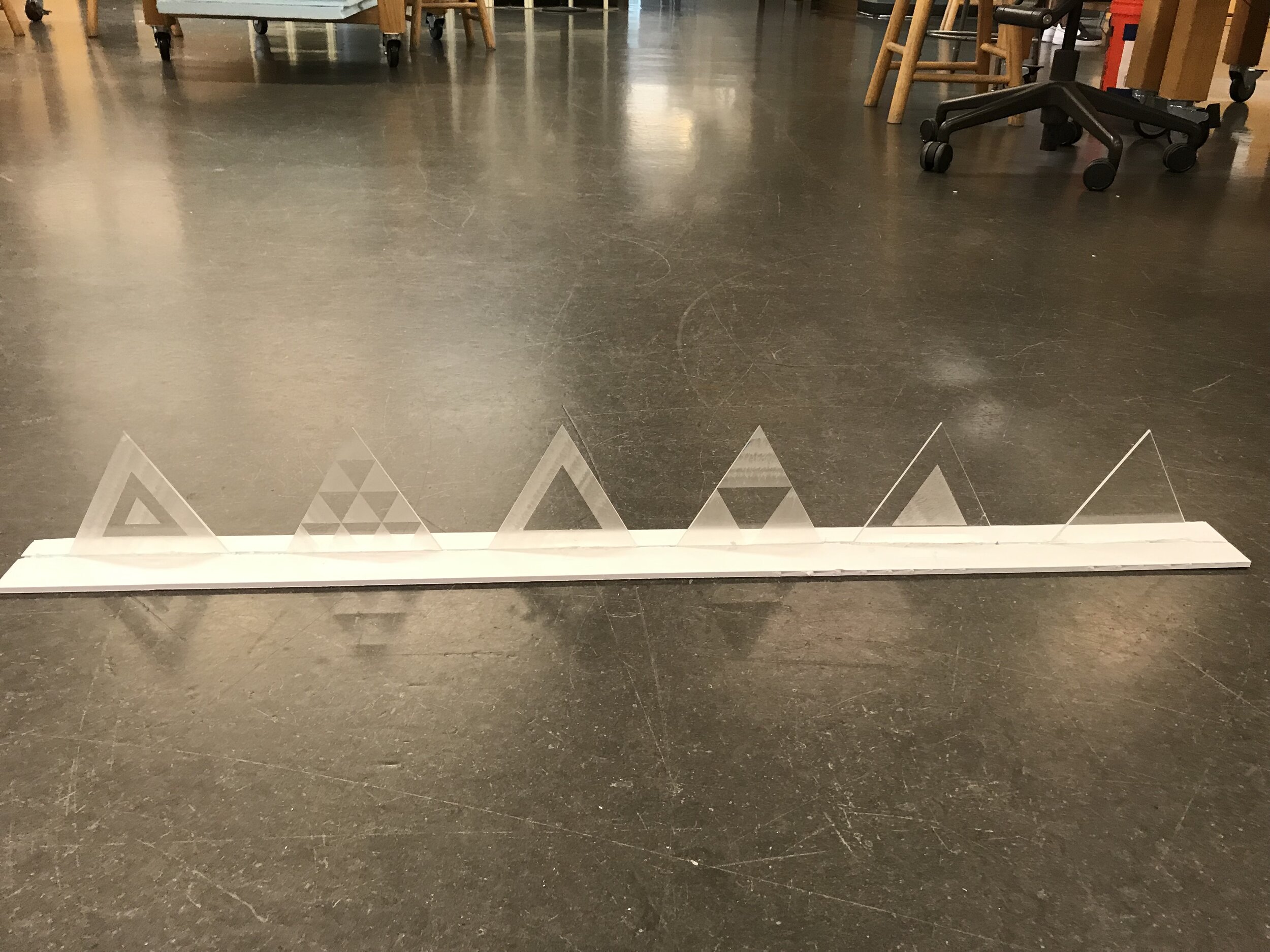

Thankfully our entire team was very passionate about iteration and prototyping, so despite it being so late into the 10-week term, we were able to create more than 5 prototypes to test. Our design developed into a LED light housed in a triangular structure.

One iteration after another with various materials. From left to right: 3D printed material, wooden and laser cut housing encased in foam, wooden structure with beanies as padding and weight, foam core with acrylic, and foam core and puddy.

Testing the durability and bounce distance of the different materials and structures.

Testing how effective each laser cut acrylic pattern is at diffusing light and gaining people’s attention.

The Final Prototype

Our final prototype, the TriAndGlow emergency triangle is a triangular light that firefighters can throw out the window on the way to a roadside accident and store in a compartment in the cab. It is fast, compact, and visible with a weighted to side to minimize rolling on the road upon impact.

Key Takeaways

Don’t be afraid to pivot directions no matter what stage.

Always keep the user’s needs in mind.

Look past the implied solution.

Put yourself in the user’s hoes. User feedback and testing is crucial for gaining insights on how to improve the product.

User feedback session with the Hanover Fire Department.